Kaist

Korean

Awards News

College of Engineering News

-

Distinguished Professor Sang Yup Lee Honored with ..

< Distinguished Professor Sang Yup Lee > Vice President for Research Sang Yup Lee received the 2021 Charles D. Scott Award from the Society for Industrial Microbiology and Biotechnology. Distinguished Professor Lee from the Department of Chemical and Biomolecular Engineering at KAIST is the first Asian awardee. The Charles D. Scott Award, initiated in 1995, recognizes individuals who have made significant contributions to enable and further the use of biotechnology to produce fuels and chemicals. The award is named in honor of Dr. Charles D. Scott, who founded the Symposium on Biomaterials, Fuels, and Chemicals and chaired the conference for its first ten years. Professor Lee has pioneered systems metabolic engineering and developed various micro-organisms capable of producing a wide range of fuels, chemicals, materials, and natural compounds, many of them for the first time. Some of the breakthroughs include the microbial production of gasoline, diacids, diamines, PLA and PLGA polymers, and several natural products. More recently, his team has developed a microbial strain capable of the mass production of succinic acid, a monomer for manufacturing polyester, with the highest production efficiency to date, as well as a Corynebacterium glutamicum strain capable of producing high-level glutaric acid. They also engineered for the first time a bacterium capable of producing carminic acid, a natural red colorant that is widely used for food and cosmetics. Professor Lee is one of the Highly Cited Researchers (HCR), ranked in the top 1% by citations in their field by Clarivate Analytics for four consecutive years from 2017. He is the first Korean fellow ever elected into the National Academy of Inventors in the US and one of 13 scholars elected as an International Member of both the National Academy of Sciences and the National Academy of Engineering in the USA. The awards ceremony will take place during the Symposium on Biomaterials, Fuels, and Chemicals held online from April 26.

-

Mobile Clinic Module Wins Red Dot and iF Design Aw..

< Mobile Clinic Module developed by the Korea Aid for Respiratory Epidemic initiative. > The Mobile Clinic Module (MCM), an inflatable negative pressure ward building system developed by the Korea Aid for Respiratory Epidemic (KARE) initiative at KAIST, gained international acclaim by winning the prestigious Red Dot Design Award and iF Design Award. The MCM was recognized as one of the Red Dot Product Designs of the Year. It also won four iF Design Awards in communication design, interior architecture, user interface, and user experience. Winning the two most influential design awards demonstrates how product design can make a valuable contribution to help contain pandemics and reflects new consumer trends for dealing with pandemics. Designed to be patient friendly, even in the extreme medical situations such as pandemics or triage, the MCM is the result of collaborations among researchers in a variety of fields including mechanical engineering, computing, industrial and systems engineering, medical hospitals, and engineering companies. The research team was led by Professor Tek-Jin Nam from the Department of Industrial Design. The MCM is expandable, moveable, and easy to store through a combination of negative pressure frames, air tents, and multi-functional panels. Positive air pressure devices supply fresh air from outside the tent. An air pump and controller maintain air beam pressure, while filtering exhausted air from inside. An internal air information monitoring system efficiently controls inside air pressure and purifies the air. It requires only one-fourth of the volume of existing wards and takes up approximately 40% of their weight. The unit can be transported in a 40-foot container truck. MCMs are now located at the Korea Institute of Radiological & Medical Sciences and Jeju Vaccine Center and expect to be used at many other facilities. KARE is developing antiviral solutions and devices such as protective gear, sterilizers, and test kits to promptly respond to the pandemic. More than 100 researchers at KAIST are collaborating with industry and clinical hospitals to develop antiviral technologies that will improve preventive measures, diagnoses, and treatments. Professor Nam said, “Our designers will continue to identify the most challenging issues, and try to resolve them by realizing user-friendly functions. We believe this will significantly contribute to relieving the drastic need for negative pressure beds and provide a place for monitoring patients with moderate symptoms. We look forward to the MCM upgrading epidemic management resources around the globe.” (END)

-

Team USRG’s Winning Streak Continues at the AI Gra..

< Team USRG won the AI Grand Challenge 2020 for the second consecutive year. > Team USRG (Unmanned Systems Research Group) led by Professor Hyunchul Shim from the School of Electrical Engineering has won the AI Grand Challenge 2020 held on Nov. 23 at Kintex in Ilsan, Kyonggi-do for the second consecutive year. The team received 7.7 million KRW in research funding from the Ministry of Science and ICT, the organizer of the challenge. The team took a little over two minutes to complete the rescue operation mission of the challenge. The mission included swerving around seven obstacles, airdropping an aid package, and safely landing after identifying the landing spot. Their drone is the only one that successfully passed through a 10-meter tunnel out of five pre-qualified teams: three from universities and two from companies. The AI Grand Challenge, which began in 2017, was designed to promote AI technology and its applications for addressing high-risk technical challenges, especially for conducting complex disaster relief operations. For autonomous flying drones, swerving to avoid objects has always been an essential skill and a big challenge. For their flawless performance in the rescue operation, the team loaded an AI algorithm and upgraded their drone by improving the LiDAR-based localization system and a stronger propulsion system to carry more sensors. The drone weighs 2.4 kg and carries a small yet powerful computer with a GPU. This AI-powered drone can complete rescue missions more efficiently in complicated and disastrous environments by precisely comprehending where the drone should go without needing GPS. The team also designed an all-in-one prop guard and installed a gripper onto the bottom of the drone to hold the aid package securely. “We tried hard to improve our localization system better to resolve issues we had in the previous event,” said Professor Shim. Two PhD candidates, Han-Sob Lee and Bo-Sung Kim played a critical role in developing this drone. After their two-year winning streak, their prize money now totals 2.4 billion KRW, equivalent to the winning prize of the DARPA Challenge. As the winning team, they will collaborate with other champions at the AI track challenge to develop rescue mission technology for a more complex environment. “The importance of AI technology is continuing to grow and the government is providing large amounts of funding for research in this field. We would like to develop very competitive technology that will work in the real world,” Professor Shim added. His group is investigating a wide array of AI technologies applicable to unmanned vehicles including indoor flying drones, self-driving cars, delivery robots, and a tram that circles the campus. < Two PhD candidates, Han-Sob Lee and Bo-Sung Kim make a final touch for the competition. >

-

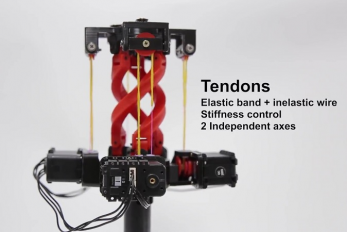

Feel the Force with ElaStick

ElaStick, a handheld variable stiffness display, renders the dynamic haptic response of a flexible object Haptic controllers play an important role in providing rich and immersive virtual reality experiences. Professor Andrea Bianchi’s team in the Department of Industrial Design recreated the haptic response of flexible objects made of different materials and with different shapes by changing the stiffness of a custom-controller – ElaStick. ElaStick is a portable hand-held force-feedback controller that is capable of rendering the illusion of how flexible and deformable objects feel when held in the hand. This VR haptic controller can change its stiffness in two directions independently and continuously. Since providing haptic feedback enhances the VR experience, researchers have suggested numerous approaches for rendering the physical properties of virtual objects - such as weights, the movement of mass, impacts, and damped oscillations. The research team designed a new mechanism based on a quaternion joint and four variable-stiffness tendons. The quaternion joint is a two-DoF bending joint that enables ElaStick to bend and oscillate in any direction using a pair of tendons with varying stiffness. In fact, each tendon around the joint is made of a series of elastic rubber bands and inelastic fishing lines and can vary its stiffness by changing the proportion of the two materials. Thanks to these structures, each pair of tendons can behave independently, controlling the anisotropic characteristics of the entire device. “The main challenge was to implement the mechanism to control the stiffness while maintaining independence between deformations in two perpendicular directions,” said Professor Bianchi. The research team successfully measured the relative threshold of human perception on the stiffness of a handheld object. The results showed that the just-noticeable difference (JND) of human perception of stiffness is at most about 30% of the change from the initial value. It also found that appropriate haptic responses significantly enhance the quality of the VR experience. The research team surveyed the perceived realism, immersion, and enjoyment of participants after they played with various flexible objects in VR. “It is meaningful that the haptic feedback of a flexible object was mechanically reproduced and its effectiveness in VR was proven. ElaStick has succeeded in implementing a novel mechanism to recreate the dynamic response of flexible objects that mimic real ones, suggesting a new category of haptic feedback that can be provided in VR,” explained Professor Bianchi. The team plans to extend the ElaStick’s applications, from being used merely as a game controller to driving simulations, medical training, and many other digital contexts. This research, led by MS candidate Neung Ryu, won the Best Paper Award at the ACM UIST 2020 (the ACM Symposium on User Interface Software & Technology) last month. -Profile Professor Andrea Bianchi Makinteract.kaist.ac.kr Department of Industrial Design KAIST

-

‘WalkON Suit 4’ Releases Paraplegics from Wheelcha..

- KAIST Athletes in ‘WalkON Suit 4’ Dominated the Cybathlon 2020 Global Edition. - Paraplegic athletes Byeong-Uk Kim and Joohyun Lee from KAIST’s Team Angel Robotics won a gold and a bronze medal respectively at the Cybathlon 2020 Global Edition last week. ‘WalkON Suit 4,’ a wearable robot developed by the Professor Kyoungchul Kong’s team from the Department of Mechanical Engineering topped the standings at the event with double medal success. Kim, the former bronze medallist, clinched his gold medal by finishing all six tasks in 3 minutes and 47 seconds, whereas Lee came in third with a time of 5 minutes and 51 seconds. TWIICE, a Swiss team, lagged 53 seconds behind Kim’s winning time to be the runner-up. < Byeong-Uk Kim (left) and Joohyun Lee (right) > Cybathlon is a global championship, organized by ETH Zurich, which brings together people with physical disabilities to compete using state-of-the-art assistive technologies to perform everyday tasks. The first championship was held in 2016 in Zurich, Switzerland. Due to the COVID-19 pandemic, the second championship was postponed twice and held in a new format in a decentralized setting. A total of 51 teams from 20 countries across the world performed the events in their home bases in different time zones instead of traveling to Zurich. Under the supervision of a referee and timekeeper, all races were filmed and then reviewed by judges. KAIST’s Team Angel Robotics participated in the Powered Exoskeleton Race category, where nine pilots representing five nations including Korea, Switzerland, the US, Russia, and France competed against each other. The team installed their own arena and raced at the KAIST Main Campus in Daejeon according to the framework, tasks, and rules defined by the competition committee. The two paraplegic pilots were each equipped with exoskeletal devices, the WalkON Suit 4, and undertook six tasks related to daily activities. The WalkON Suit 4 recorded the fastest walking speed for a complete paraplegic ever reported. For a continuous walk, it achieved a maximum speed of 40 meters per minute. This is comparable to the average walking pace of a non-disabled person, which is around two to four kilometers per hour. The research team raised the functionality of the robot by adding technology that can observe the user’s level of anxiety and external factors like the state of the walking surface, so it can control itself intelligently. The assistive functions a robot should provide vary greatly with the environment, and the WalkON Suit 4 made it possible to analyze the pace of the user within 30 steps and provide a personally optimized walking pattern, enabling a high walking speed. < WalkON Suit 4 > The six tasks that Kim and Lee had to complete were:1) sitting and standing back up, 2) navigating around obstacles while avoiding collisions, 3) stepping over obstacles on the ground, 4) going up and down stairs, 5) walking across a tilted path, and 6) climbing a steep slope, opening and closing a door, and descending a steep slope. < Overview of the Powered Exoskeleton Race. > Points were given based on the accuracy of each completed task, and the final scores were calculated by adding all of the points that were gained in each attempt, which lasted 10 minutes. Each pilot was given three opportunities and used his/her highest score. Should pilots have the same final score, the pilot who completed the race in the shortest amount of time would win. Kim said in his victory speech that he was so thrilled to see all his and fellow researchers’ years of hard work paying off. “This will be a good opportunity to show how outstanding Korean wearable robot technologies are,” he added. Lee, who participated in the competition for the first time, said, “By showing that I can overcome my physical disabilities with robot technology, I’d like to send out a message of hope to everyone who is tired because of COVID-19”. Professor Kong’s team collaborated in technology development and pilot training with their colleagues from Angel Robotics Co., Ltd., Severance Rehabilitation Hospital, Yeungnam University, Stalks, and the Institute of Rehabilitation Technology. Footage from the competition is available at the Cybathlon’s official website. (END)

-

Professor Kyu-Young Whang Donates Toward the 50th ..

< Professor Euijong Whang on behalf of his father Professor Kyu-Young Whang pose with President Shin (right) at the donation ceremony. > Distinguished Professor Kyu-Young Whang from the School of Computing made a gift of 100 million KRW toward the construction of the 50th Anniversary Memorial Building during a ceremony on November 3 at the Daejeon campus. Distinguished Professor Whang’s son Professor Euijong Whang from the School of Electrical Engineering presented the gift at the ceremony. “As a member of the first class of KAIST, I feel very delighted to play a part in the fundraising campaign for the 50th anniversary celebration. This is also a token of appreciation to my alma mater and I look forward to alumni and the KAIST community joining this campaign,” Professor Whang said on behalf of his father. Distinguished Professor Whang was a member of the first graduating class of KAIST who served as the president of KAIST Alumni Association. He completed his master’s degree at KAIST in 1975 and his PhD at Stanford University in 1984. Joining KAIST faculty in 1990, he led the Advanced IT Research Center and ERC of the National Research Foundation of Korea. He is a life fellow at IEEE and an ACM fellow. KAIST will name the “Kyu-Young Whang and Jong-Hye Song Seminar Room” at the 50th Anniversary Memorial Building. The ground will be broken in 2022 for construction of the building.

-

Taesik Gong Named Google PhD Fellow

< PhD Candidate Taesik Gong > PhD candidate Taesik Gong from the School of Computing was named a 2020 Google PhD Fellow in the field of machine learning. The Google PhD Fellowship Program has recognized and supported outstanding graduate students in computer science and related fields since 2009. Gong is one of two Korean students chosen as the recipients of Google Fellowships this year. A total of 53 students across the world in 12 fields were awarded this fellowship. Gong’s research on condition-independent mobile sensing powered by machine learning earned him this year’s fellowship. He has published and presented his work through many conferences including ACM SenSys and ACM UbiComp, and has worked at Microsoft Research Asia and Nokia Bell Labs as a research intern. Gong was also the winner of the NAVER PhD Fellowship Award in 2018. (END)

-

Professor Jungwon Kim Named Scientist of October

< Professor Jungwon Kim > Professor Jungwon Kim from the Department of Mechanical Engineering was selected as the ‘Scientist of the Month’ for October 2020 by the Ministry of Science and ICT and the National Research Foundation of Korea. Professor Kim was recognized for his contributions to expanding the horizons of the basics of precision engineering through his research on multifunctional ultrahigh-speed, high-resolution sensors. He received 10 million KRW in prize money. Professor Kim was selected as the recipient of this award in celebration of “Measurement Day”, which commemorates October 26 as the day in which King Sejong the Great established a volume measurement system. Professor Kim discovered that the time difference between the pulse of light created by a laser and the pulse of the current produced by a light-emitting diode was as small as 100 attoseconds (10-16 seconds). He then developed a unique multifunctional ultrahigh-speed, high-resolution Time-of-Flight (TOF) sensor that could take measurements of multiple points at the same time by sampling electric light. The sensor, with a measurement speed of 100 megahertz (100 million vibrations per second), a resolution of 180 picometers (1/5.5 billion meters), and a dynamic range of 150 decibels, overcame the limitations of both existing TOF techniques and laser interferometric techniques at the same time. The results of this research were published in Nature Photonics on February 10, 2020. Professor Kim said, “I’d like to thank the graduate students who worked passionately with me, and KAIST for providing an environment in which I could fully focus on research. I am looking forward to the new and diverse applications in the field of machine manufacturing, such as studying the dynamic phenomena in microdevices, or taking ultraprecision measurement of shapes for advanced manufacturing.” (END)

-

Professor Jaehyouk Choi, IT Young Engineer of the ..

< Professor Jaehyouk Choi > Professor Jaehyouk Choi from the KAIST School of Electrical Engineering won the ‘IT Young Engineer Award’ for 2020. The award was co-presented by the Institute of Electrical and Electronics Engineers (IEEE) and the Institute of Electronics Engineers of Korea (IEIE), and sponsored by the Haedong Science and Culture Foundation. The ‘IT Young Engineer Award’ selects only one mid-career scientist or engineer 40 years old or younger every year, who has made a great contribution to academic or technological advancements in the field of IT. Professor Choi’s research topics include high-performance semiconductor circuit design for ultrahigh-speed communication systems including 5G communication. In particular, he is widely known for his field of the ‘ultra-low-noise, high-frequency signal generation circuit,’ key technology for next-generation wired and wireless communications, as well as for memory systems. He has published 64 papers in SCI journals and at international conferences, and applied for and registered 25 domestic and international patents. Professor Choi is also an active member of the Technical Program Committee of international symposiums in the field of semiconductor circuits including the International Solid-State Circuits Conference (ISSCC) and the European Solid-State Circuit Conference (ESSCIRC). Beginning this year, he also serves as a distinguished lecturer at the IEEE Solid-State Circuit Society (SSCS). (END)

-

Professor Jee-Hwan Ryu Receives IEEE ICRA 2020 Out..

< Professor Jee-Hwan Ryu > Professor Jee-Hwan Ryu from the Department of Civil and Environmental Engineering was selected as this year’s winner of the Outstanding Reviewer Award presented by the Institute of Electrical and Electronics Engineers International Conference on Robotics and Automation (IEEE ICRA). The award ceremony took place on June 5 during the conference that is being held online May 31 through August 31 for three months. The IEEE ICRA Outstanding Reviewer Award is given every year to the top reviewers who have provided constructive and high-quality thesis reviews, and contributed to improving the quality of papers published as results of the conference. Professor Ryu was one of the four winners of this year’s award. He was selected from 9,425 candidates, which was approximately three times bigger than the candidate pool in previous years. He was strongly recommended by the editorial committee of the conference. (END)

-

Dr. Dong-Hyun Cho at KARI Receives the 16th Jeong ..

< From left: PhD candidate Yongtae Yun at KAIST, Dr. Dong-Hyun Cho at KARI, Seonju Yim at Kongju National University High School, and MS-PhD candidate Haun-Min Lee at Korea University > Dr. Dong-Hyun Cho, a senior researcher at the Korea Aerospace Research Institute (KARI), was honored as the recipient of the 16th Jeong Hun Cho Award. The award recognizes young scientists in the field of aerospace engineering. Dr. Cho earned his MS and PhD degrees from the KAIST Department of Aerospace Engineering in 2012, and served as a researcher at the Satellite Technology Research Center (SaTReC) at KAIST, before joining the Future Convergence Research Division at KARI. He won this year’s award and received 25 million KRW in prize money. Jeong Hun Cho, who was a PhD candidate in the Department of Aerospace Engineering at KAIST, passed away in a tragic lab accident in May 2003 and was awarded an honorary doctorate posthumously. His family endowed the award and scholarship in his memory. Since 2005, the scholarship has selected three young scholars every year who specialize in aerospace engineering from Cho’s alma maters of KAIST, Korea University, and Kongju National University High School. Dr. Dong-Hyun Cho was selected as this year’s awardee in recognition of his studies on the development and operation of KARISMA, a comprehensive software package for space debris collision risk management. Dr. Cho built a terrestrial testbed and produced a model for the development of a space debris elimination algorithm. He published six papers in SCI-level journals and wrote 35 symposium papers in the field of space development. He also applied or registered approximately 40 patents both in Korea and internationally. The Award Committee also selected three students as scholarship recipients: PhD candidate Yongtae Yun from the Department of Aerospace Engineering at KAIST received 4 million KRW, MS-PhD candidate Haun-Min Lee from the School of Mechanical Engineering at Korea University received 4 million KRW, and Seonju Yim from Kongju National University High School received 3 million KRW. (END)

-

Jeju Inspired Packaging by ID+IM Design Lab Wins 2..

< Professor Sangmin Bae > A water bottle designed by researchers from the ID+IM Design Laboratory led by Professor Sangmin Bae from the Department of Industrial Design won the packaging section of the 2020 iF Design Award. The iF Design Award, hosted by the Hannover Exhibition Center in Germany, is one of the three major international design competitions. It receives more than 7,000 submissions from participants representing 60 countries. The Jeju Yong-Am-Soo (which means ‘volcanic mineral water’ in English) bottle design was a product of an academic-industrial cooperation project carried out by Professor Bae’s team and a Korean confectionery company, Orion Corporation, to create a design for a premium mineral water bottle. The motif of the awarded design was the beautiful nature of Jeju Island in Korea. The columnar joints and the horizon of Jeju Island were each represented by horizontal and vertical lines, completing a simple yet sensuous design. The mystical volcanic Mount Halla printed on the transparent front-label of the bottle represents the daytime of Jeju Island, while the rear-label design, which is reflected through the transparent front-label, symbolizes the nighttime of Jeju Island. By putting the Orion constellation, a symbol of tourist’s guide, right above the Orion Corporation’s brand logo, Professor Bae’s team ambiently promotes the company’s identity. Although the design uses a significantly smaller amount of materials than traditional water bottles, it can withstand about four times the pressure and weight. The efficient structure therefore shows excellence in both aesthetic and functional areas. Professor Bae said, “I am happy with the fact that the result of this academic-industrial cooperation project became mass-produced through commercialization and was recognized by an international design award.” He continued, “Even though it was difficult for my team to come up with the design that fits both manufacturing and the distribution processes, we worked hard to achieve the structural and functional aspects, while also expressing beauty through its appearance.” < Awarded Design >