Kaist

Korean

Faculty News

-

Team KAIST to Race at CES 2022 Autonomous Challeng..

Five top university autonomous racing teams will compete in a head-to-head passing competition in Las Vegas < Team KAIST of self-driving team from the Unmanned System Research Group (USRG) advised by Professor Hyunchul Shim (second from right) > A self-driving racing team from the KAIST Unmanned System Research Group (USRG) advised by Professor Hyunchul Shim will compete at the Autonomous Challenge at the Consumer Electronic Show (CES) on January 7, 2022. The head-to-head, high speed autonomous racecar passing competition at the Las Vegas Motor Speedway will feature the finalists and semifinalists from the Indy Autonomous Challenge in October of this year. Team KAIST qualified as a semifinalist at the Indy Autonomous Challenge and will join four other university teams including the winner of the competition, Technische Universität München. Team KAIST’s AV-21 vehicle is capable of driving on its own at more than 200km/h will be expected to show a speed of more than 300 km/h at the race.The participating teams are: 1. KAIST 2. EuroRacing : University of Modena and Reggio Emilia (Italy), University of Pisa (Italy), ETH Zürich (Switzerland), Polish Academy of Sciences (Poland) 3. MIT-PITT-RW, Massachusetts Institute of Technology, University of Pittsburgh, Rochester Institute of Technology, University of Waterloo (Canada) 4.PoliMOVE – Politecnico di Milano (Italy), University of Alabama 5.TUM Autonomous Motorsport – Technische Universität München (Germany) Professor Shim’s team is dedicated to the development and validation of cutting edge technologies for highly autonomous vehicles. In recognition of his pioneering research in unmanned system technologies, Professor Shim was honored with the Grand Prize of the Minister of Science and ICT on December 9. “We began autonomous vehicle research in 2009 when we signed up for Hyundai Motor Company’s Autonomous Driving Challenge. For this, we developed a complete set of in-house technologies such as low-level vehicle control, perception, localization, and decision making.” In 2019, the team came in third place in the Challenge and they finally won this year. For years, his team has participated in many unmanned systems challenges at home and abroad, gaining recognition around the world. The team won the inaugural 2016 IROS autonomous drone racing and placed second in the 2018 IROS Autonomous Drone Racing Competition. They also competed in 2017 MBZIRC, ranking fourth in Missions 2 and 3, and fifth in the Grand Challenge. Most recently, the team won the first round of Lockheed Martin’s Alpha Pilot AI Drone Innovation Challenge. The team is now participating in the DARPA Subterranean Challenge as a member of Team CoSTAR with NASA JPL, MIT, and Caltech. “We have accumulated plenty of first-hand experience developing autonomous vehicles with the support of domestic companies such as Hyundai Motor Company, Samsung, LG, and NAVER. In 2017, the autonomous vehicle platform “EureCar” that we developed in-house was authorized by the Korean government to lawfully conduct autonomous driving experiment on public roads,” said Professor Shim. The team has developed various key technologies and algorithms related to unmanned systems that can be categorized into three major components: perception, planning, and control. Considering the characteristics of the algorithms that make up each module, their technology operates using a distributed computing system. Since 2015, the team has been actively using deep learning algorithms in the form of perception subsystems. Contextual information extracted from multi-modal sensory data gathered via cameras, lidar, radar, GPS, IMU, etc. is forwarded to the planning subsystem. The planning module is responsible for the decision making and planning required for autonomous driving such as lane change determination and trajectory planning, emergency stops, and velocity command generation. The results from the planner are fed into the controller to follow the planned high-level command. The team has also developed and verified the possibility of an end-to-end deep learning based autonomous driving approach that replaces a complex system with one single AI network.

-

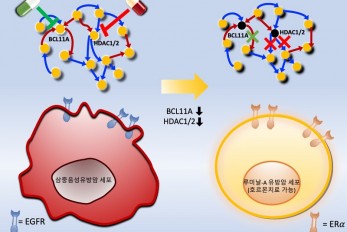

Connecting the Dots to Find New Treatments for Bre..

Systems biologists uncovered new ways of cancer cell reprogramming to treat drug-resistant cancers < Professor Kwang-Hyun Cho and colleagues have developed a mathematical model and identified optimal targets reprogramming basal-like cancer cells into hormone therapy-responsive luminal-A cells by deciphering the complex molecular interactions within these cells through a systems biological approach. > Scientists at KAIST believe they may have found a way to reverse an aggressive, treatment-resistant type of breast cancer into a less dangerous kind that responds well to treatment. The study involved the use of mathematical models to untangle the complex genetic and molecular interactions that occur in the two types of breast cancer, but could be extended to find ways for treating many others. The study’s findings were published in the journal Cancer Research. Basal-like tumours are the most aggressive type of breast cancer, with the worst prognosis. Chemotherapy is the only available treatment option, but patients experience high recurrence rates. On the other hand, luminal-A breast cancer responds well to drugs that specifically target a receptor on their cell surfaces, called estrogen receptor alpha (ERα). KAIST systems biologist Kwang-Hyun Cho and colleagues analyzed the complex molecular and genetic interactions of basal-like and luminal-A breast cancers to find out if there might be a way to switch the former to the latter and give patients a better chance to respond to treatment. To do this, they accessed large amounts of cancer and patient data to understand which genes and molecules are involved in the two types. They then input this data into a mathematical model that represents genes, proteins and molecules as dots and the interactions between them as lines. The model can be used to conduct simulations and see how interactions change when certain genes are turned on or off. “There have been a tremendous number of studies trying to find therapeutic targets for treating basal-like breast cancer patients,” says Cho. “But clinical trials have failed due to the complex and dynamic nature of cancer. To overcome this issue, we looked at breast cancer cells as a complex network system and implemented a systems biological approach to unravel the underlying mechanisms that would allow us to reprogram basal-like into luminal-A breast cancer cells.” Using this approach, followed by experimental validation on real breast cancer cells, the team found that turning off two key gene regulators, called BCL11A and HDAC1/2, switched a basal-like cancer signalling pathway into a different one used by luminal-A cancer cells. The switch reprograms the cancer cells and makes them more responsive to drugs that target ERα receptors. However, further tests will be needed to confirm that this also works in animal models and eventually humans. “Our study demonstrates that the systems biological approach can be useful for identifying novel therapeutic targets,” says Cho. The researchers are now expanding its breast cancer network model to include all breast cancer subtypes. Their ultimate aim is to identify more drug targets and to understand the mechanisms that could drive drug-resistant cells to turn into drug-sensitive ones. This work was supported by the National Research Foundation of Korea, the Ministry of Science and ICT, Electronics and Telecommunications Research Institute, and the KAIST Grand Challenge 30 Project. -Publication Sea R. Choi, Chae Young Hwang, Jonghoon Lee, and Kwang-Hyun Cho, “Network Analysis Identifies Regulators of Basal-like Breast Cancer Reprogramming and Endocrine Therapy Vulnerability,” Cancer Research, November 30. (doi:10.1158/0008-5472.CAN-21-0621) -Profile Professor Kwang-Hyun Cho Laboratory for Systems Biology and Bio-Inspired Engineering Department of Bio and Brain Engineering KAIST

-

Professor Sung-Ju Lee’s Team Wins the Best Paper a..

< Professor Sung-Ju Lee, Professor Eun Kyoung, Choe Hyunsung Cho, Daeun Choi, Donghwi Kim, Wan Ju Kang (from left) > A research team led by Professor Sung-Ju Lee at the School of Electrical Engineering won the Best Paper Award and the Methods Recognition Award from ACM CSCW (International Conference on Computer-Supported Cooperative Work and Social Computing) 2021 for their paper “Reflect, not Regret: Understanding Regretful Smartphone Use with App Feature-Level Analysis”. Founded in 1986, CSCW has been a premier conference on HCI (Human Computer Interaction) and Social Computing. This year, 340 full papers were presented and the best paper awards are given to the top 1% papers of the submitted. Methods Recognition, which is a new award, is given “for strong examples of work that includes well developed, explained, or implemented methods, and methodological innovation.” Hyunsung Cho (KAIST alumus and currently a PhD candidate at Carnegie Mellon University), Daeun Choi (KAIST undergraduate researcher), Donghwi Kim (KAIST PhD Candidate), Wan Ju Kang (KAIST PhD Candidate), and Professor Eun Kyoung Choe (University of Maryland and KAIST alumna) collaborated on this research. The authors developed a tool that tracks and analyzes which features of a mobile app (e.g., Instagram’s following post, following story, recommended post, post upload, direct messaging, etc.) are in use based on a smartphone’s User Interface (UI) layout. Utilizing this novel method, the authors revealed which feature usage patterns result in regretful smartphone use. Professor Lee said, “Although many people enjoy the benefits of smartphones, issues have emerged from the overuse of smartphones. With this feature level analysis, users can reflect on their smartphone usage based on finer grained analysis and this could contribute to digital wellbeing.” < Research achievements diagram : Application feature level usage analysis / UI LAYOUT Analysis >

-

A Study Shows Reactive Electrolyte Additives Impro..

Stable electrode-electrolyte interfaces constructed by fluorine- and nitrogen-donating ionic additives provide an opportunity to improve high-performance lithium metal batteries < A combination of lithium difluoro (bisoxalato) phosphate as an F donor and lithium nitrate as an N donor with different electron accepting abilities and adsorption tendencies improves the cycle performance of Li|NCM811 full cells through the creation of a dual-layer SEI on a Li metal anode and a protective CEI on a Ni-rich cathode. > A research team showed that electrolyte additives increase the lifetime of lithium metal batteries and remarkably improve the performance of fast charging and discharging. Professor Nam-Soon Choi’s team from the Department of Chemical and Biomolecular Engineering at KAIST hierarchized the solid electrolyte interphase to make a dual-layer structure and showed groundbreaking run times for lithium metal batteries. The team applied two electrolyte additives that have different reduction and adsorption properties to improve the functionality of the dual-layer solid electrolyte interphase. In addition, the team has confirmed that the structural stability of the nickel-rich cathode was achieved through the formation of a thin protective layer on the cathode. This study was reported in Energy Storage Materials. Securing high-energy-density lithium metal batteries with a long lifespan and fast charging performance is vital for realizing their ubiquitous use as superior power sources for electric vehicles. Lithium metal batteries comprise a lithium metal anode that delivers 10 times higher capacity than the graphite anodes in lithium-ion batteries. Therefore, lithium metal is an indispensable anode material for realizing high-energy rechargeable batteries. However, undesirable reactions among the electrolytes with lithium metal anodes can reduce the power and this remains an impediment to achieving a longer battery lifespan. Previous studies only focused on the formation of the solid electrolyte interphase on the surface of the lithium metal anode. The team designed a way to create a dual-layer solid electrolyte interphase to resolve the instability of the lithium metal anode by using electrolyte additives, depending on their electron accepting ability and adsorption tendencies. This hierarchical structure of the solid electrolyte interphase on the lithium metal anode has the potential to be further applied to lithium-alloy anodes, lithium storage structures, and anode-free technology to meet market expectations for electrolyte technology. The batteries with lithium metal anodes and nickel-rich cathodes represented 80.9% of the initial capacity after 600 cycles and achieved a high Coulombic efficiency of 99.94%. These remarkable results contributed to the development of protective dual-layer solid electrolyte interphase technology for lithium metal anodes. Professor Choi said that the research suggests a new direction for the development of electrolyte additives to regulate the unstable lithium metal anode-electrolyte interface, the biggest hurdle in research on lithium metal batteries. She added that anode-free secondary battery technology is expected to be a game changer in the secondary battery market and electrolyte additive technology will contribute to the enhancement of anode-free secondary batteries through the stabilization of lithium metal anodes. This research was funded by the Technology Development Program to Solve Climate Change of the National Research Foundation in Korea funded by the Ministry of Science, ICT & Future Planning and the Technology Innovation Program funded by the Ministry of Trade, Industry & Energy, and Hyundai Motor Company. - Publication Saehun Kim, Sung O Park, Min-Young Lee, Jeong-A Lee, Imanuel Kristanto, Tae Kyung Lee, Daeyeon Hwang, Juyoung Kim, Tae-Ung Wi, Hyun-Wook Lee, Sang Kyu Kwak, and Nam Soon Choi, “Stable electrode-electrolyte interfaces constructed by fluorine- and nitrogen-donating ionic additives for high-performance lithium metal batteries,” Energy Storage Materials, 45, 1-13 (2022), (doi: https://doi.org/10.1016/j.ensm.2021.10.031) - Profile Professor Nam-Soon Choi Energy Materials Laboratory Department of Chemical and Biomolecular Engineering KAIST

-

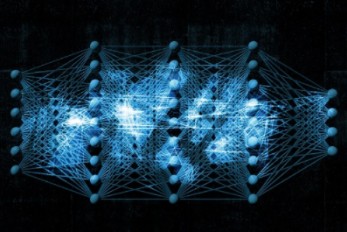

Deep Learning Framework to Enable Material Design ..

Researchers propose a deep neural network-based forward design space exploration using active transfer learning and data augmentation < Figure 1: Schematic of deep learning framework for material design space exploration. Schematic of gradual expansion of reliable prediction domain of DNN based on the addition of data generated from the hyper-heuristic genetic algorithm and active transfer learning. > A new study proposed a deep neural network-based forward design approach that enables an efficient search for superior materials far beyond the domain of the initial training set. This approach compensates for the weak predictive power of neural networks on an unseen domain through gradual updates of the neural network with active transfer learning and data augmentation methods. Professor Seungwha Ryu believes that this study will help address a variety of optimization problems that have an astronomical number of possible design configurations. For the grid composite optimization problem, the proposed framework was able to provide excellent designs close to the global optima, even with the addition of a very small dataset corresponding to less than 0.5% of the initial training data-set size. This study was reported in npj Computational Materials last month. “We wanted to mitigate the limitation of the neural network, weak predictive power beyond the training set domain for the material or structure design,” said Professor Ryu from the Department of Mechanical Engineering. Neural network-based generative models have been actively investigated as an inverse design method for finding novel materials in a vast design space. However, the applicability of conventional generative models is limited because they cannot access data outside the range of training sets. Advanced generative models that were devised to overcome this limitation also suffer from weak predictive power for the unseen domain. Professor Ryu’s team, in collaboration with researchers from Professor Grace Gu’s group at UC Berkeley, devised a design method that simultaneously expands the domain using the strong predictive power of a deep neural network and searches for the optimal design by repetitively performing three key steps. First, it searches for few candidates with improved properties located close to the training set via genetic algorithms, by mixing superior designs within the training set. Then, it checks to see if the candidates really have improved properties, and expands the training set by duplicating the validated designs via a data augmentation method. Finally, they can expand the reliable prediction domain by updating the neural network with the new superior designs via transfer learning. Because the expansion proceeds along relatively narrow but correct routes toward the optimal design (depicted in the schematic of Fig. 1), the framework enables an efficient search. As a data-hungry method, a deep neural network model tends to have reliable predictive power only within and near the domain of the training set. When the optimal configuration of materials and structures lies far beyond the initial training set, which frequently is the case, neural network-based design methods suffer from weak predictive power and become inefficient. Researchers expect that the framework will be applicable for a wide range of optimization problems in other science and engineering disciplines with astronomically large design space, because it provides an efficient way of gradually expanding the reliable prediction domain toward the target design while avoiding the risk of being stuck in local minima. Especially, being a less-data-hungry method, design problems in which data generation is time-consuming and expensive will benefit most from this new framework. The research team is currently applying the optimization framework for the design task of metamaterial structures, segmented thermoelectric generators, and optimal sensor distributions. “From these sets of on-going studies, we expect to better recognize the pros and cons, and the potential of the suggested algorithm. Ultimately, we want to devise more efficient machine learning-based design approaches,” explained Professor Ryu.This study was funded by the National Research Foundation of Korea and the KAIST Global Singularity Research Project. -Publication Yongtae Kim, Youngsoo, Charles Yang, Kundo Park, Grace X. Gu, and Seunghwa Ryu, “Deep learning framework for material design space exploration using active transfer learning and data augmentation,” npj Computational Materials (https://doi.org/10.1038/s41524-021-00609-2) -Profile Professor Seunghwa Ryu Mechanics & Materials Modeling Lab Department of Mechanical Engineering KAIST

-

A Mechanism Underlying Most Common Cause of Epilep..

An interdisciplinary study shows that neurons carrying somatic mutations in MTOR can lead to focal epileptogenesis via non-cell-autonomous hyperexcitability of nearby nonmutated neurons < Image 1: Neurons carrying somatic mutations in MTOR lead to focal epileptogenesis via non-cell autonomous hyperexcitability of nearby non-mutated neurons. (Left) Neurons with mTOR mutation (green) observed in a mouse brain section image. (Middle) Network model consisting of a small portion of mutated and a large portion of nearby non-mutated neurons. (Right) Mitigated hyperactivity of non-mutated neurons after the treatment of inhibitor of adenosine kinase. > During fetal development, cells should migrate to the outer edge of the brain to form critical connections for information transfer and regulation in the body. When even a few cells fail to move to the correct location, the neurons become disorganized and this results in focal cortical dysplasia. This condition is the most common cause of seizures that cannot be controlled with medication in children and the second most common cause in adults. Now, an interdisciplinary team studying neurogenetics, neural networks, and neurophysiology at KAIST has revealed how dysfunctions in even a small percentage of cells can cause disorder across the entire brain. They published their results on June 28 in Annals of Neurology. The work builds on a previous finding, also by a KAIST scientists, who found that focal cortical dysplasia was caused by mutations in the cells involved in mTOR, a pathway that regulates signaling between neurons in the brain. “Only 1 to 2% of neurons carrying mutations in the mTOR signaling pathway that regulates cell signaling in the brain have been found to include seizures in animal models of focal cortical dysplasia,” said Professor Jong-Woo Sohn from the Department of Biological Sciences. “The main challenge of this study was to explain how nearby non-mutated neurons are hyperexcitable.” Initially, the researchers hypothesized that the mutated cells affected the number of excitatory and inhibitory synapses in all neurons, mutated or not. These neural gates can trigger or halt activity, respectively, in other neurons. Seizures are a result of extreme activity, called hyperexcitability. If the mutated cells upend the balance and result in more excitatory cells, the researchers thought, it made sense that the cells would be more susceptible to hyperexcitability and, as a result, seizures. “Contrary to our expectations, the synaptic input balance was not changed in either the mutated or non-mutated neurons,” said Professor Jeong Ho Lee from the Graduate School of Medical Science and Engineering. “We turned our attention to a protein overproduced by mutated neurons.” The protein is adenosine kinase, which lowers the concentration of adenosine. This naturally occurring compound is an anticonvulsant and works to relax vessels. In mice engineered to have focal cortical dysplasia, the researchers injected adenosine to replace the levels lowered by the protein. It worked and the neurons became less excitable. “We demonstrated that augmentation of adenosine signaling could attenuate the excitability of non-mutated neurons,” said Professor Se-Bum Paik from the Department of Bio and Brain Engineering. The effect on the non-mutated neurons was the surprising part, according to Paik. “The seizure-triggering hyperexcitability originated not in the mutation-carrying neurons, but instead in the nearby non-mutated neurons,” he said. The mutated neurons excreted more adenosine kinase, reducing the adenosine levels in the local environment of all the cells. With less adenosine, the non-mutated neurons became hyperexcitable, leading to seizures. “While we need further investigate into the relationship between the concentration of adenosine and the increased excitation of nearby neurons, our results support the medical use of drugs to activate adenosine signaling as a possible treatment pathway for focal cortical dysplasia,” Professor Lee said. The Suh Kyungbae Foundation, the Korea Health Technology Research and Development Project, the Ministry of Health & Welfare, and the National Research Foundation in Korea funded this work. -Publication: Koh, H.Y., Jang, J., Ju, S.H., Kim, R., Cho, G.-B., Kim, D.S., Sohn, J.-W., Paik, S.-B. and Lee, J.H. (2021), ‘Non–Cell Autonomous Epileptogenesis in Focal Cortical Dysplasia’ Annals of Neurology, 90: 285 299. (https://doi.org/10.1002/ana.26149) -Profile Professor Jeong Ho Lee Translational Neurogenetics Lab https://tnl.kaist.ac.kr/ Graduate School of Medical Science and Engineering KAIST Professor Se-Bum Paik Visual System and Neural Network Laboratory http://vs.kaist.ac.kr/ Department of Bio and Brain Engineering KAIST Professor Jong-Woo Sohn Laboratory for Neurophysiology, https://sites.google.com/site/sohnlab2014/home Department of Biological Sciences KAIST Dr. Hyun Yong Koh Translational Neurogenetics Lab Graduate School of Medical Science and Engineering KAIST Dr. Jaeson Jang Ph.D. Visual System and Neural Network Laboratory Department of Bio and Brain Engineering KAIST Sang Hyeon Ju M.D. Laboratory for Neurophysiology Department of Biological Sciences KAIST

-

Aline and Blow-yancy Win the Red Dot Design Awards..

Professor Lee sought ‘sustainability’ while developing Aline to meet the growing awareness of ESG (environmental, social, and governance) investing. ESG investing relies on independent ratings that help consumers assess a company’s behavior and policies when it comes to its social impact. Aline’s personal value index with six main criteria translates values into sustainable finance. By gathering data from the initial survey and regular value updates, the index is weighted according to the user’s values. Based on the index, the investment portfolio will be adjusted, and consumption against the values will be tracked. Blow-yancy is a diving VR device for neutral buoyancy training. Blow-yancy’s VR mask helps divers feel like they are wearing an actual diving mask. Users can breathe through a regulator with a built-in breathing sensor. It allows training like actual diving without going into the water, therefore enabling safer diving. “We got an idea that about 74% of scuba divers come into contact with corals underwater at least once and that can cause an emergency situation. Divers who cannot maintain neutral buoyance will experience a tough time avoiding them,” said Professor Lee. The hardware consists of a nose covering VR mask, a regulator with a built-in breath sensor, and a controller for virtual BCD control. Blow-yancy’s five virtual missions were organized according to the diving process required by PADI, a professional diving education institute. Professor Lee’s team already received eight recognitions at the iF Design Award in April. Professor Lee said, “We will continue to develop the best UX design items that will improve our global recognition.”

-

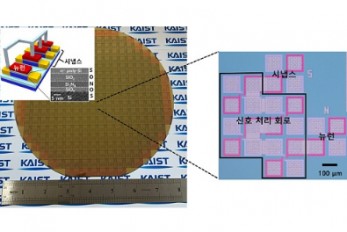

Brain-Inspired Highly Scalable Neuromorphic Hardwa..

Neurons and synapses based on single transistor can dramatically reduce the hardware cost and accelerate the commercialization of neuromorphic hardware < Single transistor neurons and synapses fabricated using a standard silicon CMOS process. They are co-integrated on the same 8-inch wafer. > KAIST researchers fabricated a brain-inspired highly scalable neuromorphic hardware by co-integrating single transistor neurons and synapses. Using standard silicon complementary metal-oxide-semiconductor (CMOS) technology, the neuromorphic hardware is expected to reduce chip cost and simplify fabrication procedures. The research team led by Yang-Kyu Choi and Sung-Yool Choi produced a neurons and synapses based on single transistor for highly scalable neuromorphic hardware and showed the ability to recognize text and face images. This research was featured in Science Advances on August 4. Neuromorphic hardware has attracted a great deal of attention because of its artificial intelligence functions, but consuming ultra-low power of less than 20 watts by mimicking the human brain. To make neuromorphic hardware work, a neuron that generates a spike when integrating a certain signal, and a synapse remembering the connection between two neurons are necessary, just like the biological brain. However, since neurons and synapses constructed on digital or analog circuits occupy a large space, there is a limit in terms of hardware efficiency and costs. Since the human brain consists of about 1011 neurons and 1014 synapses, it is necessary to improve the hardware cost in order to apply it to mobile and IoT devices. To solve the problem, the research team mimicked the behavior of biological neurons and synapses with a single transistor, and co-integrated them onto an 8-inch wafer. The manufactured neuromorphic transistors have the same structure as the transistors for memory and logic that are currently mass-produced. In addition, the neuromorphic transistors proved for the first time that they can be implemented with a ‘Janus structure’ that functions as both neuron and synapse, just like coins have heads and tails. Professor Yang-Kyu Choi said that this work can dramatically reduce the hardware cost by replacing the neurons and synapses that were based on complex digital and analog circuits with a single transistor. "We have demonstrated that neurons and synapses can be implemented using a single transistor," said Joon-Kyu Han, the first author. "By co-integrating single transistor neurons and synapses on the same wafer using a standard CMOS process, the hardware cost of the neuromorphic hardware has been improved, which will accelerate the commercialization of neuromorphic hardware,” Han added.This research was supported by the National Research Foundation (NRF) and IC Design Education Center (IDEC). -Publication Joon-Kyu Han, Sung-Yool Choi, Yang-Kyu Choi, et al.“Cointegration of single-transistor neurons and synapses by nanoscale CMOS fabrication for highly scalable neuromorphic hardware,” Science Advances (DOI: 10.1126/sciadv.abg8836) -Profile Professor Yang-Kyu Choi Nano-Oriented Bio-Electronics Lab https://sites.google.com/view/nobelab/ School of Electrical Engineering KAIST Professor Sung-Yool Choi Molecular and Nano Device Laboratory https://www.mndl.kaist.ac.kr/ School of Electrical Engineering KAIST

-

3D Visualization and Quantification of Bioplastic ..

3D holographic microscopy leads to in-depth analysis of bacterial cells accumulating the bacterial bioplastic, polyhydroxyalkanoate (PHA) < Time-lapse movie of recombinant E. coli cells for 520 minutes. The red color indicates in vivo PHA granules. The movie shows PHA granule formation and distribution during the cell division process. > A research team at KAIST has observed how bioplastic granule is being accumulated in living bacteria cells through 3D holographic microscopy. Their 3D imaging and quantitative analysis of the bioplastic ‘polyhydroxyalkanoate’ (PHA) via optical diffraction tomography provides insights into biosynthesizing sustainable substitutes for petroleum-based plastics. The bio-degradable polyester polyhydroxyalkanoate (PHA) is being touted as an eco-friendly bioplastic to replace existing synthetic plastics. While carrying similar properties to general-purpose plastics such as polyethylene and polypropylene, PHA can be used in various industrial applications such as container packaging and disposable products. PHA is synthesized by numerous bacteria as an energy and carbon storage material under unbalanced growth conditions in the presence of excess carbon sources. PHA exists in the form of insoluble granules in the cytoplasm. Previous studies on investigating in vivo PHA granules have been performed by using fluorescence microscopy, transmission electron microscopy (TEM), and electron cryotomography. < Figure: Schematic process of 3D optical diffraction tomography for the bacterial cell accumulating bioplastic polyhydroxyalkanoate (PHA). A cell sample is illuminated at multiple sequential illumination angles (Left, Top). From the raw holograms recorded at individual angles (Left, Bottom), quantitative amplitude and phase information (Middle) is retrieved and the 3D refractive index distribution (Right, Top) is reconstructed. The 3D rendering image of the sample is then obtained (Right, Bottom). > These techniques have generally relied on the statistical analysis of multiple 2D snapshots of fixed cells or the short-time monitoring of the cells. For the TEM analysis, cells need to be fixed and sectioned, and thus the investigation of living cells was not possible. Fluorescence-based techniques require fluorescence labeling or dye staining. Thus, indirect imaging with the use of reporter proteins cannot show the native state of PHAs or cells, and invasive exogenous dyes can affect the physiology and viability of the cells. Therefore, it was difficult to fully understand the formation of PHA granules in cells due to the technical limitations, and thus several mechanism models based on the observations have been only proposed. The team of metabolic engineering researchers led by Distinguished Professor Sang Yup Lee and Physics Professor YongKeun Park, who established the startup Tomocube with his 3D holographic microscopy, reported the results of 3D quantitative label-free analysis of PHA granules in individual live bacterial cells by measuring the refractive index distributions using optical diffraction tomography. The formation and growth of PHA granules in the cells of Cupriavidus necator, the most-studied native PHA (specifically, poly(3-hydroxybutyrate), also known as PHB) producer, and recombinant Escherichia coli harboring C. necator PHB biosynthesis pathway were comparatively examined. From the reconstructed 3D refractive index distribution of the cells, the team succeeded in the 3D visualization and quantitative analysis of cells and intracellular PHA granules at a single-cell level. In particular, the team newly presented the concept of “in vivo PHA granule density.” Through the statistical analysis of hundreds of single cells accumulating PHA granules, the distinctive differences of density and localization of PHA granules in the two micro-organisms were found. Furthermore, the team identified the key protein that plays a major role in making the difference that enabled the characteristics of PHA granules in the recombinant E. coli to become similar to those of C. necator. The research team also presented 3D time-lapse movies showing the actual processes of PHA granule formation combined with cell growth and division. Movies showing the living cells synthesizing and accumulating PHA granules in their native state had never been reported before. Professor Lee said, “This study provides insights into the morphological and physical characteristics of in vivo PHA as well as the unique mechanisms of PHA granule formation that undergo the phase transition from soluble monomers into the insoluble polymer, followed by granule formation. Through this study, a deeper understanding of PHA granule formation within the bacterial cells is now possible, which has great significance in that a convergence study of biology and physics was achieved. This study will help develop various bioplastics production processes in the future.” This work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries (Grants NRF-2012M1A2A2026556 and NRF-2012M1A2A2026557) and the Bio & Medical Technology Development Program (Grant No. 2021M3A9I4022740) from the Ministry of Science and ICT (MSIT) through the National Research Foundation (NRF) of Korea to S.Y.L. This work was also supported by the KAIST Cross-Generation Collaborative Laboratory project. -Publication So Young Choi, Jeonghun Oh, JaeHwang Jung, YongKeun Park, and Sang Yup Lee. Three-dimensional label-free visualization and quantification of polyhydroxyalkanoates in individual bacterial cell in its native state. PNAS(https://doi.org./10.1073/pnas.2103956118) -Profile Distinguished Professor Sang Yup Lee Metabolic Engineering and Synthetic Biology http://mbel.kaist.ac.kr/ Department of Chemical and Biomolecular Engineering KAIST Endowed Chair Professor YongKeun Park Biomedical Optics Laboratory https://bmokaist.wordpress.com/ Department of Physics KAIST

-

Prof. Changho Suh Named the 2021 James L. Massey A..

< Professor Changho Suh > Professor Changho Suh from the School of Electrical Engineering was named the recipient of the 2021 James L.Massey Award. The award recognizes outstanding achievement in research and teaching by young scholars in the information theory community. The award is named in honor of James L. Massey, who was an internationally acclaimed pioneer in digital communications and revered teacher and mentor to communications engineers. Professor Suh is a recipient of numerous awards, including the 2021 James L. Massey Research & Teaching Award for Young Scholars from the IEEE Information Theory Society, the 2019 AFOSR Grant, the 2019 Google Education Grant, the 2018 IEIE/IEEE Joint Award, the 2015 IEIE Haedong Young Engineer Award, the 2013 IEEE Communications Society Stephen O. Rice Prize, the 2011 David J. Sakrison Memorial Prize (the best dissertation award in UC Berkeley EECS), the 2009 IEEE ISIT Best Student Paper Award, the 2020 LINKGENESIS Best Teacher Award (the campus-wide Grand Prize in Teaching), and the four Departmental Teaching Awards (2013, 2019, 2020, 2021). Dr. Suh is an IEEE Information Theory Society Distinguished Lecturer, the General Chair of the Inaugural IEEE East Asian School of Information Theory, and a Member of the Young Korean Academy of Science and Technology. He is also an Associate Editor of Machine Learning for the IEEE Transactions on Information Theory, the Editor for the IEEE Information Theory Newsletter, a Column Editor for IEEE BITS the Information Theory Magazine, an Area Chair of NeurIPS 2021, and on the Senior Program Committee of IJCAI 2019–2021.

-

Prof. Junil Choi Receives the Neal Shepherd Memori..

< Professor Junil Choi > Professor Junil Choi of the School of Electrical Engineering received the 2021 Neal Shepherd Memorial Award from the IEEE Vehicular Technology Society. The award recognizes the most outstanding paper relating to radio propagation published in major journals over the previous five years. Professor Cho, the recipient of the 2015 IEEE Signal Processing Society’s and the 2019 IEEE Communications Society’s Best Paper Award, was selected as the awardee for his paper titled “The Impact of Beamwidth on Temporal Channel Variation in Vehicular Channels and Its Implications” in IEEE Transaction on Vehicular Technology in 2017. In this paper, Professor Choi and his team derived the channel coherence time for a wireless channel as a function of the beamwidth, taking both Doppler effect and pointing error into consideration. The results showed that a nonzero optimal beamwidth exists that maximizes the channel coherence time. To reduce the impact of the overhead of doing realignment in every channel coherence time, the paper showed that the beams should be realigned every beam coherence time for the best performance. Professor Choi said, “It is quite an honor to receive this prestigious award following Professor Joonhyun Kang who won the IEEE VTS’s Jack Neubauer Memorial Award this year. It shows that our university’s pursuit of excellence in advanced research is being well recognized.”

-

Repurposed Drugs Present New Strategy for Treating..

Virtual screening of 6,218 drugs and cell-based assays identifies best therapeutic medication candidates < Figure: A schematic representation of computational drug repurposing strategy. Docking-based virtual screening can rapidly identify novel compounds for COVID-19 treatment among from the collection of approved and clinical trial drugs. > A joint research group from KAIST and Institut Pasteur Korea has identified repurposed drugs for COVID-19 treatment through virtual screening and cell-based assays. The research team suggested the strategy for virtual screening with greatly reduced false positives by incorporating pre-docking filtering based on shape similarity and post-docking filtering based on interaction similarity. This strategy will help develop therapeutic medications for COVID-19 and other antiviral diseases more rapidly. This study was reported at the Proceedings of the National Academy of Sciences of the United States of America (PNAS). Researchers screened 6,218 drugs from a collection of FDA-approved drugs or those under clinical trial and identified 38 potential repurposed drugs for COVID-19 with this strategy. Among them, seven compounds inhibited SARS-CoV-2 replication in Vero cells. Three of these drugs, emodin, omipalisib, and tipifarnib, showed anti-SARS-CoV-2 activity in human lung cells, Calu-3. Drug repurposing is a practical strategy for developing antiviral drugs in a short period of time, especially during a global pandemic. In many instances, drug repurposing starts with the virtual screening of approved drugs. However, the actual hit rate of virtual screening is low and most of the predicted drug candidates are false positives. The research group developed effective filtering algorithms before and after the docking simulations to improve the hit rates. In the pre-docking filtering process, compounds with similar shapes to the known active compounds for each target protein were selected and used for docking simulations. In the post-docking filtering process, the chemicals identified through their docking simulations were evaluated considering the docking energy and the similarity of the protein-ligand interactions with the known active compounds. The experimental results showed that the virtual screening strategy reached a high hit rate of 18.4%, leading to the identification of seven potential drugs out of the 38 drugs initially selected. “We plan to conduct further preclinical trials for optimizing drug concentrations as one of the three candidates didn’t resolve the toxicity issues in preclinical trials,” said Woo Dae Jang, one of the researchers from KAIST. “The most important part of this research is that we developed a platform technology that can rapidly identify novel compounds for COVID-19 treatment. If we use this technology, we will be able to quickly respond to new infectious diseases as well as variants of the coronavirus,” said Distinguished Professor Sang Yup Lee. This work was supported by the KAIST Mobile Clinic Module Project funded by the Ministry of Science and ICT (MSIT) and the National Research Foundation of Korea (NRF). The National Culture Collection for Pathogens in Korea provided the SARS-CoV-2 (NCCP43326). -Publication Woo Dae Jang, Sangeun Jeon, Seungtaek Kim, and Sang Yup Lee. Drugs repurposed for COVID-19 by virtual screening of 6,218 drugs and cell-based assay. Proc. Natl. Acad. Sci. U.S.A. (https://doi/org/10.1073/pnas.2024302118) -Profile Distinguished Professor Sang Yup Lee Metabolic &Biomolecular Engineering National Research Laboratory http://mbel.kaist.ac.kr Department of Chemical and Biomolecular Engineering KAIST